|

Hints & Tricks - Moulded brick and stonewalls I like to take short-cuts to the best

result and here's one which I found very useful. There is a wide

range of stone walls, brick walls, tunnel entrances and stone

arches available in moulded plastic in our Hobby shops. However,

they are quite expensive and the plastic is hard and not so easy

to apply. My landscape usually contains a lot of walls, since

I have limited space and of course a lot of tracks. Engraved walls

are great if you are skilled and lot of time, but I save those

for the front part of my layout.

|

|

|||

|

|

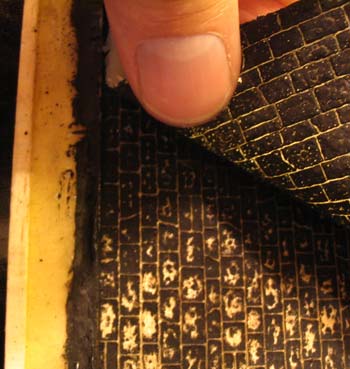

The glue has now dried enough to be removed from the mould. |

|

Wall production starts |

|

|

Making the first moulded wall The soft stone wall Good luck! / Martin T . |