| - MRR TUTORIALS - BENCHWORK - INDEX |

OPEN BENCHWORK FOR THE MODEL RAILWAY

The most common type of framework - easy, cheap and quick to build.

|

|

In this video I describe the planning and construction of the most common type of framework, namely the so-called open framework. The open framework is easy and quick to build and it does not require much material.

This type of framework can easily be supplemented with drawers for storage or for the electronics boxes used to run trains and control switches and signals.

.

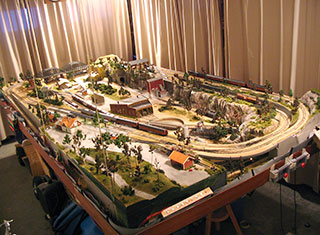

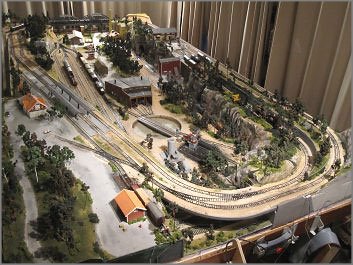

EXAMPLES OF THE FINAL RESULT:

|

|

|

OVERVIEW DIFFERENT TYPES OF BENCHWORKS

Here are some common types of benchwork used for model railways

Open Grid framework

This is one of the most popular types of benchwork. It consists of a grid of wooden frames, typically made from 1x3 or 1x4 lumber. The open grid allows for easy access to wiring and scenery construction. It's versatile and can support complex track plans and varied terrain.

.

L-Girder Benchwork

This type of benchwork uses L-shaped girders made from two pieces of lumber (usually 1x2 and 1x3) fastened together. The L-girder design is strong and allows for easy attachment of risers and sub-roadbed. It's particularly useful for layouts with varying elevations.

Solid table top or Plywood board

8x4' sheet of plywood. Easy to set up and rebuild. Limit ways to have lanscape below track level

.

Hollow Core Door Benchwork

Using a hollow core door as the base for a layout is a simple and cost-effective method. It's lightweight and provides a flat, sturdy surface. This is often used for small to medium-sized layouts .

Cookie-Cutter Benchwork

This method involves cutting the sub-roadbed from a sheet of plywood in a way that allows sections to be elevated or lowered to create hills and valleys. It's often used in combination with open grid or L-girder benchwork .

Framework for

Shelf Layouts

These are narrow, wall-mounted layouts that are ideal for small spaces. They can be supported by brackets or a simple frame attached to the wall. Shelf layouts are great for linear track plans and switching operations .

Modular Benchwork

This involves building the layout in sections or modules that can be easily connected or rearranged. It's popular for club layouts or for modelers who may need to move their layout. Standards like those from the National Model Railroad Association (NMRA) or Free-mo are often used to ensure compatibility between modules.

EXAMPEL ON DIFFERENT BENCHWORKS:

Variant på ramverk baserat på L-balk |

En sk. Helix baserat på gängstänger och L-balk |

Modelljärnväg byggd på plywoodskiva |

BUILDING A MULTI-FUNCTION VALANCE

Layout illumination and room echo absorbing features increase operator comfort.

|

|

In this video we´re building a multi-function valance over the layout which features both acoustics and illumination. The reason is simple. The valance improve the over-all layout appearence. Illumination closer to the layout surface than from the ceiling makes it exponentially more efficient.

Operating several trains with sound decoders simultaneously makes lots of noice, which is reflected by the ceiling and walls and beocmes unbearable after a while. A sound absorbing valance solves that problem.

EXAMPLES OF THE FINAL RESULT:

|

|

|

MODEL RAILWAY HANGING FROM THE CEILING

Being able to hoist the Modelrailway up and down proved to be unexpectedly difficult.

Ceiling tables were a tough design problem!

My first ceiling table was made of a 20x45mm pine frame and had 12mm chipboard table top. It was bad, because it was impossible to pull up due to its enormous weight (about 60kg). It also didn't take long before there was a slope down from each joint.

The 2nd table was at least pull-up!

My second table was built on the same framework, but had a table top made of carefully double-sided varnished 4mm plywood. The table was pull-up, but after a short time it unfortunately looked like a roller coaster. Now the pine beams also started to look flabby.

3rd time a winner!

Parts of the framework were replaced with 15x25mm O-profile aluminum that I sawed into the I-beams I built from pine strips. This way, the transverse aluminum beams were undivided from table edge to table edge. All joints were reinforced with pieces of L-profile aluminum, which were screwed with self-tapping screws (see picture). Furthermore, I screwed a pine strip on top of the aluminum profile. Why, you may ask?!

Table top made of Foamboard

The table top was also replaced with a thick light, stiff ground insulation board munfatured by Platon. The board is available at all hardware stores as ground insulation for basement floors. It is purple in color and about 16mm thick. The boards are also edge cutted, so that they are easy to glue together to make a table top in the desired size. I glued it with regular wood glue and it worked well.

Ceiling suspension intact

My idea with block rollers in expander bolts and a pulley to make it easier to lift the table has worked well. When the table is empty, it is easy to pull up. With a complete train system mounted, a little more force is required. It is still possible without a winch or other aids.

Motorization also problematic

The first motorization was powered by 6pcs 24VDC worm-geared motors. They were able to lift the system, but unfortunately at different speeds, which caused the carts to start rolling. Furthermore, they were unable to keep the table up on the ceiling even though I short-circuited the motors in the end position. I then changed to a single large down-geared motor that pulled all the steel cables at the same time. Unfortunately, this was not good enough either, so I decided to scrap the idea.

EXAMPLES OF THE FINAL RESULT:

The table seen from below in elevated position |

The rope arrangements with pulley and blocks |

The layout seen from above in lowered position |